After months of wrenching, troubleshooting, and more late nights than I can count, the Mustang finally roared back to life.

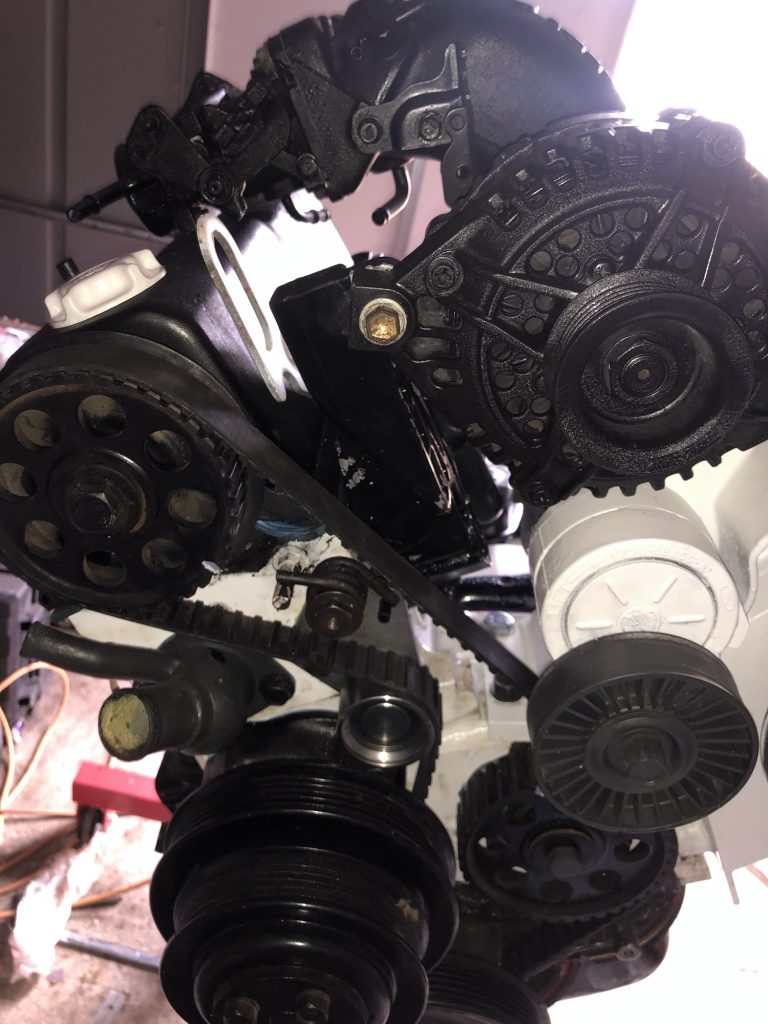

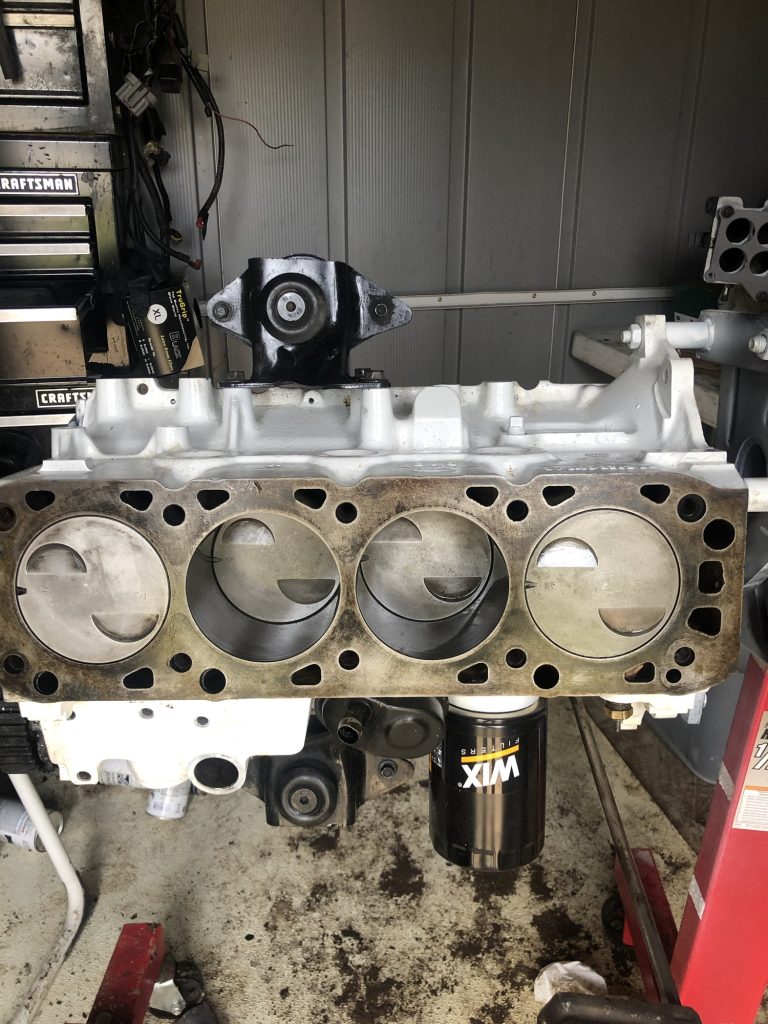

This project has been equal parts obsession, education, and exercise in patience. From building the harness to relocating the battery, setting up the Microsquirt ECU, and chasing down electrical gremlins, every system has demanded attention. But hearing it fire up—especially knowing every wire and connection was laid out by hand—made it all worth it.

The Startup

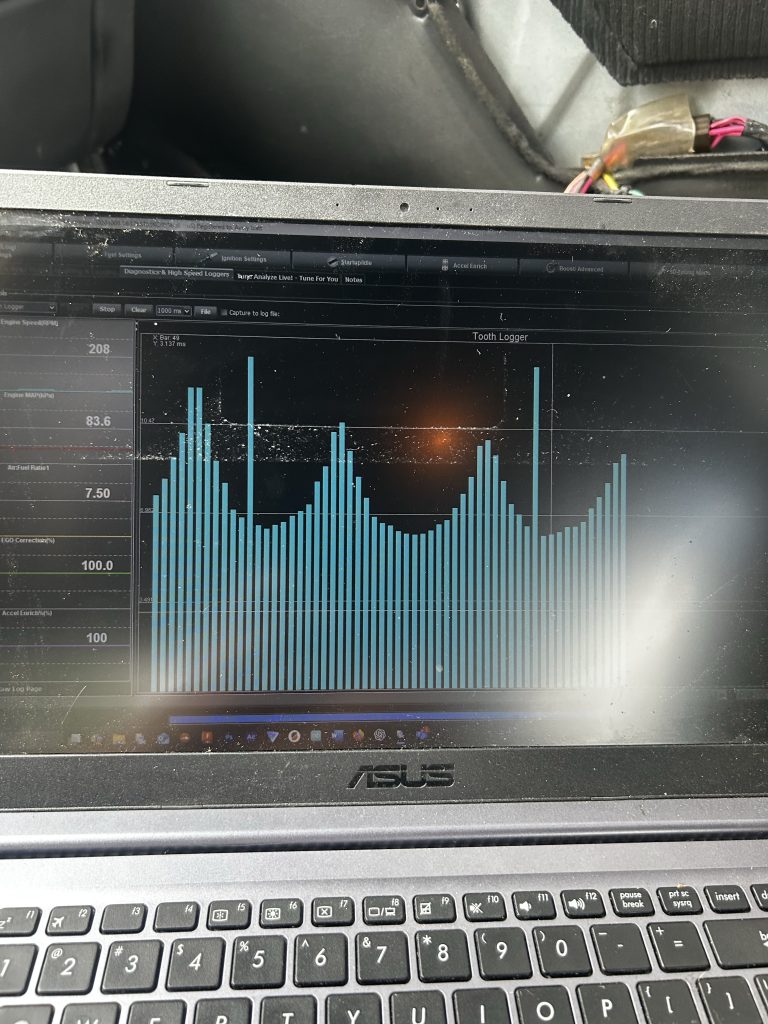

I’ll be sharing a video of the first successful start. Even though it’s just idling in the driveway, this moment marks a huge milestone. The Microsquirt is online, sensors are reading correctly, and the ignition finally behaving after sorting out the voltage drop and verifying the coil wiring. It’s not perfectly tuned yet, but the fundamentals are there.

Battery Relocation

One of the big changes was moving the battery to the trunk. That meant upgrading to 1/0 gauge cable to handle cranking amps, integrating a cutoff switch, battery charger and re-routing grounds to avoid the voltage drop issues I ran into early on. Even with careful planning, I ended up chasing low voltage at the starter and ECU, if you’re considering a similar setup, be prepared to measure everything twice and still have to improvise.

Electrical Debugging

If you’ve been following along, you know the turn signals and hazards decided to quit altogether. After pulling modules apart and checking power feeds, I confirmed the flasher wasn’t the culprit, just a lot of old wiring and tired switches. Replacing the multifunction stalk resolved the high beams refusing to stay on, and I’m still tidying up the last of the loose ends.

Tuning Learning Curve

Moving to a standalone ECU has been a serious learning experience. From setting up the base fuel tables to configuring the trigger wheel and spark output, it’s a process that demands patience and constant iteration. Even now, I’m still refining idle control and enrichment settings. But compared to the old carb setup, the control and data visibility are on another level.

Next Steps

Now that it’s running, the next phase is fine-tuning the fuel and ignition maps, tracking down any remaining wiring gremlins, and starting some road tests. There’s still a lot to do before it’s ready for consistent driving, but this was the biggest hurdle.

I’ll post updates as the tuning progresses. For anyone considering a Microsquirt conversion on an old Foxbody, don’t underestimate the learning curve but also don’t underestimate how satisfying it is when everything finally comes together.

[Watch the startup video here.]